39272S.S - Optical Encoder Installation Instructions

PDF Instructions for replacing the 39272S.S Optical Encoder

These instructions are written assuming that you will have ample room around Opener to perform this repair. Some rare instances will require removal of the unit from it’s mounting hardware and repair made on a bench or floor. Refer to your Owners Manual or Installation Poster for proper assembly and carefully read and understand all warnings and cautions pertaining to your unit.

39272S.S 24V DC Opto Replacement For Chain & Belt Operators

WARNING

BE SURE ELECTRICAL POWER HAS BEEN DISCONNECTED FROM THE OPENER PRIOR TO REMOVING THE MOTOR COVER.

WARNING

ANY AND ALL REPAIRS MADE TO THIS UNIT MUST BE PERFORMED WITH THE DOOR DISCONNECTED FROM THE OPENER AND IN THE CLOSED POSITION.

Tools required: Standard slotted and Phillips head screwdrivers, small slotted screwdriver, 5/16” nut driver.

CLOSE THE GARAGE DOOR PRIOR TO REPAIR.

1. Remove power from operator.

2. Press down on tabs to remove lens.

3. Remove light bulbs.

4. Note locations and remove BWC (Basic Wall Control) and STB (Safe-T-Beam®) wires. Use small screwdriver to press in on orange tabs to remove wires. FIG. 1.

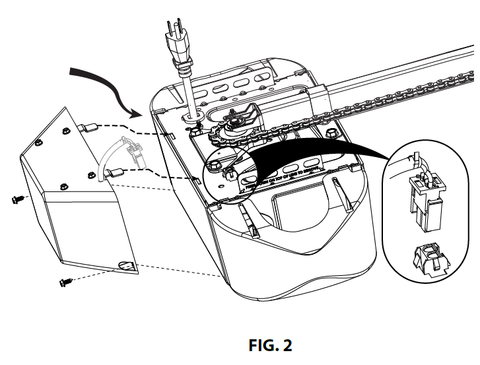

5. If equipped, unplug and remove battery backup (BBU) from the back of motor housing. Fig. 2.

6. Using a 5/16” nut driver or common screw driver, remove the 2 opener cover screws and remove opener cover. FIG-3A

7. Note the locations and disconnect lights, transformer primary, AC power, red & black motor wires, transformer secondary, and encoder harnesses. FIG. 4

8. Using a 1/4” nut driver or common screwdriver, remove 2 control board mounting screws and remove control board. FIG. 5.

9. Carefully remove all harnesses from harness keepers.

10. Remove Opto Assembly cover screws (3-3/16”) leave harness plugged into assembly FIG. 3B.

11. Install replacement Opto Assembly and install cover screws (3).

12. Carefully slide all harnesses back into harness keepers.

13. Reinstall the control board, harnesses, and opener cover in reverse order. Ensure that harnesses are plugged in the correct positions. See harness detail FIG. 6.

14. Reinstall BWC & STB wires, light bulb and lens.

15. Install BBU assembly onto motor housing if equipped.

16. Reapply power to operator.

NOTE: Limit settings will require reprogramming. Refer to your owners manual for detailed instructions.

IMPORTANT: Test opener functions. The door MUST reverse on contact with a 1-1/2” high object (or a 2 x 4 board laid flat) at the center of doorway on the floor. After adjusting either the force or limit of travel, retest door opener. Failure to adjust the opener properly may cause severe injury or death.

-

Genie Garage Door Opener Replacement Parts

Need help finding the right garage door opener part? Not sure which...

-

Accessories

[split] Find the right accessories for your garage door opener: The Genie...

-

Smart Device Compatible

Smart Device Compatible Garage "Can I make my garage door opener smart?"...