The Genie Company

Optical Encoder (RPM Sensor) 39153R.S- AC Screw Drive Models

Optical Encoder (RPM Sensor) 39153R.S- AC Screw Drive Models

Couldn't load pickup availability

The Optical Encoder also called the RPM sensor, is used in certain Genie model screw drive garage door openers. (See below for compatibility) This may resolve the issue of short travel problems or drifting limits on the garage door opener.

- Compatible with models; 2562, 2564, 2568, PowerLift®, GPower 900

- If you do not see your model on this list and have questions please contact Genie for compatibility questions

- Genuine Genie Replacement Part

SKU: 39153R.S

In Stock! Usually ships within 24 hours.

ASK A QUESTION View full detailsQUESTIONS & ANSWERS

Ask a Question-

My door will travel to the set open position and then start to go shorter with each opening, with that it seems to go lower also until it is so low or too much pressure at the floor it will not stay down. I can hear a clicking noise when the door starts to open , at about the first section of the rail , it is a screw drive model. This started about a week or two ago. The unit has been installed for 5 yrs ?? The model no. is 3062, but about 4 1/2 yrs ago the motor was replaced with a factory rebuilt. I can't see a number on it.I spoke with the help line and a optoluctor # 39153rs was thought to be the problem. I looked inside the housing and found that part but would need the trick on how to remove. Thanks for any help you can provide me.

-

Will this fit my opener Model 2562 S/N 130804110065JA

Yes, the Optical Encoder (RPM Sensor) 39153R.S- AC Screw Drive Models will work with the model 2562 garage door opener.

PDF Replacement instructions for 39153R.S AC Opto Sensor Assembly

AC Opto Sensor Assembly (39153R.S) Replacement

This repair will require removal of the unit from it’s mounting hardware and repairs made on a clean work surface. Refer to your Owners Manual and/or Installation Poster for proper assembly and carefully read and understand all warnings and cautions pertaining to your unit.

WARNING

BE SURE ELECTRICAL POWER HAS BEEN DISCONNECTED FROM THE INPUT POWER LINES PRIOR TO REMOVING THE MOTOR COVER.

WARNING

ANY AND ALL REPAIRS MADE TO THIS UNIT MUST BE PERFORMED WITH THE DOOR DISCONNECTED FROM THE OPENER AND IN THE CLOSED POSITION.

1. Before pulling emergency release cord, make certain people and objects are clear of door opening. Pull emergency release cord on carriage to disengage opener to close door if necessary. If unable to lower door using opener, use extreme caution manually closing door.

2. Unplug opener power cord from power receptacle.

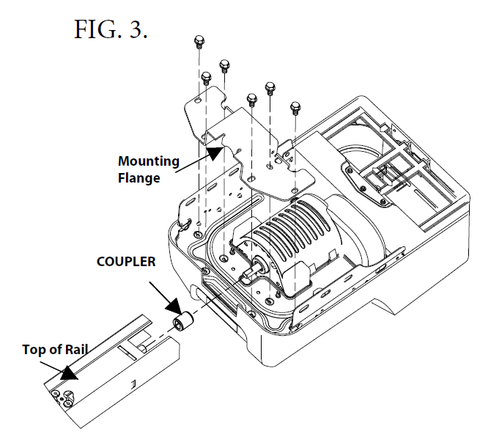

3. Open lens cover by pressing middle tab inward to swing down and remove light bulbs. FIG. 1.

4. Mark wires to help facilitate replacement and remove wall control and Safe-T-Beam wires from terminal block located on side of opener FIG. 1. Use small common screwdriver to press in on orange tabs while gently pulling wires from block.

5. Remove the cotter pin & clevis from door arm to separate door from opener. FIG. 2.

6. Remove motor head and rail assembly from mounting brackets/ hardware and set on a clean work surface.

7. Remove the 6-7/16” self-tapping bolts from the rail/motor mounting straps and pull rail from motorhead. FIG.3. Set rail assembly aside.

8. Remove two 5/16” screws securing powerhead cover to chassis and swing open to expose control board. FIG. 4.

NOTE: Do not remove control board from cover, shown for clarity only.

9. Remove grounding wires (green) from chassis. FIG. 6B.

10. Unplug these harnesses from control board. FIG. 5.

• Motor harness

• Opto harness

• AC in harness

11. Powerhead cover can now be removed from opener chassis.

12. Remove yellow and orange motor wires to start capacitor FIG. 6A

13. Remove three motor mounting bolts from motor frame FIG. 6C. Remove motor assembly.

14. Using an 11/32 socket or nut driver, press down on encoder wheel mounting clips while pulling wheel off of spline shaft. FIG. 7.

15. Remove and retain screw(s) holding encoder to motor frame and remove encoder. FIG. 8.

16. Remove and retain e-ring holding motor gear to motor shaft. FIG. 8.

17. Remove and retain motor gear. FIG. 8.

18. Install replacement 39153R.S encoder assembly with screw(s).

19. Install motor gear and e-ring to motor shaft.

20. Snap encoder wheel into place. (Interrupter fins face encoder.)

21. Install motor assembly in reverse order.

Note: Be certain to install all harnesses in the correct position being sure to install with locking tabs facing each other. (Detailed in FIG. 5)

22. Hang powerhead cover to chassis to install harnesses.

HARNESS NOTE: Check the type of circuit board installed in your opener (see FIG. 9). Use appropriate harness included with this kit.

23. Install ground wires onto chassis. (If equipped)

24. Install powerhead cover onto chassis using 2- 5/16” screws.

25. Install rail to motor head assembly using the coupler, mounting flange and 6-7/16” self-tapping screws.

26. Reinstall opener assembly in reverse order as removed. Reference your owners manual and installation poster.

27. Install wall control and Safe-T-Beam® wires.

28. Install light bulbs and close lens cover.

29. Plug opener into a receptacle.

30. Clear and reprogram limit controls per owners manual.

-

Free Shipping

We offer FREE shipping and handling on all orders that total over $17.99 and are shipped to a US address. All orders are shipped using UPS ground, directly from The Genie Company.

-

Genuine Replacements

Buying GENUINE Genie accessories and parts guarantees that you are getting quality OEM materials backed by a Genie warranty.

-

Support

Need assistance? We are here for you! We offer a wide range of customer support options including contact by phone or email, web chat services with a live agent, and a robust support section also located on our website. All customer care teams and services are based in the USA.